Vaillant Boiler Display Symbols: A Comprehensive Guide

Decoding Vaillant boiler displays is crucial for homeowners, offering insights into system status and potential issues. Understanding these symbols empowers proactive maintenance and timely repairs, ensuring optimal heating performance and longevity.

Understanding Vaillant Boiler Displays

Vaillant boiler displays are designed to communicate the boiler’s operational status through a series of symbols and, often, accompanying fault codes. These displays vary depending on the specific Vaillant model – Ecotec, Turbomax, or Ecomax – but the core principle remains consistent: providing clear, concise information to the user.

Modern Vaillant boilers typically feature digital displays, offering more detailed information than older models with simpler LED indicators. The display will show current temperature settings, operating mode (heating, hot water, or standby), and any active alerts or errors. Familiarizing yourself with the common symbols – like the flame symbol, water droplet, or temperature indicators – is the first step towards understanding your boiler’s performance. Recognizing these visual cues allows for quick identification of potential problems before they escalate into major faults, potentially saving on repair costs and ensuring consistent home comfort.

Types of Vaillant Boiler Displays

Vaillant employs several distinct display types across its boiler range, evolving with technological advancements. Older models often utilized basic LED displays, showing limited information through simple indicator lights – a flashing light might signal a fault, while a steady light indicated normal operation. However, the majority of contemporary Vaillant boilers, particularly the Ecotec range, feature sophisticated digital displays.

These digital displays present information more comprehensively, utilizing LCD or LED screens to showcase current temperature, operating mode (heating, hot water), and detailed fault codes. Some advanced models even incorporate touch screen interfaces for intuitive control and diagnostics. The information presented varies; some displays prioritize simplicity, while others offer extensive diagnostic data. Understanding which display type your Vaillant boiler has is crucial for interpreting the information presented and effectively troubleshooting any issues that may arise.

Common Display Symbols & Their Meanings

Vaillant boiler displays utilize a range of symbols to communicate system status. A consistent flame symbol signifies normal operation, indicating the burner is active and providing heat. Conversely, a flashing flame often points to an ignition fault or gas supply issue, requiring immediate attention. A snowflake symbol represents the hot water function, while a radiator symbol indicates heating mode.

Low water pressure is typically indicated by a water droplet symbol, often accompanied by a numerical pressure reading. A frozen pipe is signaled by a snowflake within a pipe icon. Error codes, displayed as “F” followed by numbers (e.g., F.28), denote specific faults – these require referencing a fault code list for accurate diagnosis. Familiarizing yourself with these common symbols empowers you to quickly assess your boiler’s condition and determine if professional assistance is needed.

Fault Codes: Decoding the Errors

Fault codes on your Vaillant boiler are essential diagnostic tools, pinpointing specific issues within the system for efficient troubleshooting and repair solutions.

F.28 & F.29: Condensate Pipe Frozen

Error codes F.28 and F.29 specifically indicate a frozen condensate pipe, a common issue during colder months. The condensate pipe is responsible for draining acidic water produced during the boiler’s efficient condensing process. When temperatures drop below freezing, this water can freeze within the pipe, causing a blockage and triggering the fault code.

This blockage prevents the boiler from safely operating, as it cannot effectively remove the condensate. Immediate action isn’t always required, as the boiler may attempt to auto-reset once the pipe thaws. However, persistent codes necessitate investigation.

Solutions include carefully thawing the pipe with warm (not boiling!) water, ensuring adequate insulation of the pipe to prevent future freezing, and verifying the pipe’s correct installation with a sufficient fall for drainage. Ignoring this issue can lead to further damage.

F.61 & F.62: Pump Issues

Fault codes F.61 and F.62 signal problems with the boiler’s circulating pump, a vital component responsible for moving hot water throughout your heating system. F.61 generally indicates the pump is running slowly or not at all, while F.62 suggests the pump is experiencing electrical issues or is completely blocked. These faults disrupt heating and hot water supply.

Potential causes include airlocks within the system, a faulty pump motor, or debris obstructing the pump’s impeller. Troubleshooting often begins with checking for blockages and bleeding the radiators to remove air. If the issue persists, the pump itself may require replacement.

Ignoring these codes can lead to overheating and potential damage to the boiler. It’s crucial to address pump issues promptly to restore efficient heating and prevent further complications. Professional diagnosis is recommended for complex cases.

F.75: Flame Detection Error

The F.75 fault code on a Vaillant boiler signifies a critical issue: the boiler is unable to detect a flame during the ignition process. This doesn’t necessarily mean there’s no gas, but rather the flame sensor isn’t registering its presence. This is a common, yet potentially serious, error requiring careful investigation.

Several factors can trigger this code, including a faulty flame sensor, a disrupted gas supply, or issues with the ignition transformer. A dirty or damaged flame sensor is a frequent culprit, preventing accurate flame detection. Troubleshooting involves visually inspecting the sensor and cleaning it carefully.

Ignoring F.75 can be dangerous, as unburnt gas can accumulate. It’s vital to avoid repeated ignition attempts. If cleaning the sensor doesn’t resolve the issue, a Gas Safe registered engineer should be contacted immediately for a thorough diagnosis and repair.

F.1: Gas Supply or Ignition Fault

The F.1 error code on a Vaillant boiler indicates a problem with either the gas supply to the boiler or a fault within the ignition system. This is a broad code, meaning pinpointing the exact cause requires systematic checking. It’s a critical error demanding prompt attention due to potential safety concerns.

Possible causes include a lack of gas to the property, a closed gas valve, a faulty gas valve within the boiler, or a malfunctioning ignition transformer. A low gas pressure can also trigger this code. Initial checks should verify gas is flowing to other appliances.

Attempting repairs without proper training is dangerous. If you suspect a gas supply issue, contact your gas provider immediately. For ignition faults, a qualified Gas Safe registered engineer is essential for diagnosis and repair, ensuring safe and effective operation of your Vaillant boiler.

Diagnostic Codes: Advanced Settings

Vaillant’s diagnostic codes, denoted by ‘d’, allow skilled technicians to fine-tune boiler performance, adjusting parameters like heating load for optimal efficiency and customized operation.

d.00: Heating Load Adjustment

The d.00 diagnostic code controls the heating load adjustment on your Vaillant boiler, a critical setting for matching the boiler’s output to your home’s heating demands. This code typically presents two options: ‘Auto’ and ‘24kW’. Selecting ‘Auto’ allows the boiler to intelligently modulate its output based on the current heating requirement, maximizing efficiency and comfort.

Conversely, setting d.00 to ‘24kW’ fixes the boiler’s output to its maximum capacity. This might be suitable for larger properties or those with consistently high heating needs, but can lead to reduced efficiency if the full output isn’t always necessary. Adjusting this setting requires accessing the boiler’s service menu and understanding the implications for both performance and energy consumption. Incorrect settings can impact heating responsiveness and overall system efficiency, so careful consideration is advised.

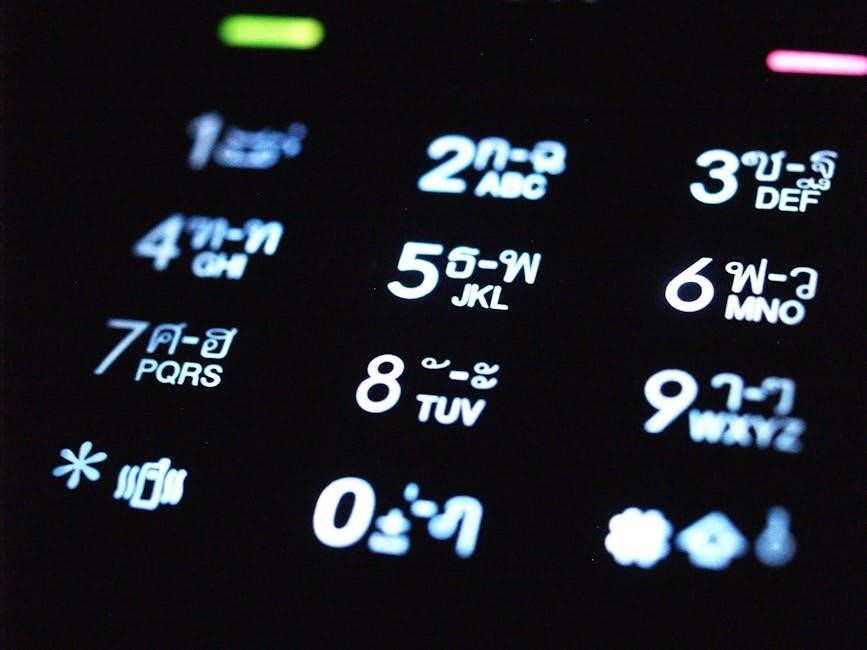

Accessing Diagnostic Codes

Unlocking Vaillant boiler diagnostic codes requires a specific sequence of button presses on the boiler’s control panel. Typically, this involves simultaneously pressing and holding two buttons – often the ‘Info’ and ‘Reset’ buttons – for a sustained period, usually around five to ten seconds. The boiler display will then transition from its normal operating view to a service or diagnostic mode.

Once in diagnostic mode, you can navigate through the various codes using the control panel buttons. The exact method varies slightly depending on the specific Vaillant boiler model, so consulting the user manual is essential. Be cautious when altering any settings within the diagnostic menu, as incorrect adjustments can affect boiler performance. It’s generally recommended to only view codes unless you possess a thorough understanding of their function.

Understanding Diagnostic Code Functions

Vaillant boiler diagnostic codes provide detailed insights into internal system parameters and operational status, extending beyond simple fault indications. Codes like ‘d.00’ (heating load adjustment) directly influence boiler output, allowing technicians to tailor performance to specific heating demands – either ‘Auto’ or a fixed 24kW setting. Other codes reveal information about water pressure, flue temperature, and gas valve operation.

These codes aren’t merely error messages; they’re tools for fine-tuning boiler efficiency and diagnosing complex issues. However, interpreting them requires specialized knowledge. Incorrectly modifying settings can lead to inefficient operation or even safety hazards; Therefore, accessing and altering diagnostic codes should ideally be performed by a Gas Safe registered engineer, ensuring both safety and optimal boiler performance. Understanding their function empowers informed troubleshooting.

Specific Model Faults

Vaillant boilers, like Ecotec, Turbomax, and Ecomax, exhibit unique fault patterns. Identifying the model is vital for accurate diagnosis and effective repair solutions.

Ecotec Faults

Ecotec boilers, renowned for their efficiency, can display specific fault codes requiring attention. A common issue is F.28/F.29, indicating a frozen condensate pipe – particularly during colder months. This necessitates checking and thawing the pipe to restore functionality. F.61 & F.62 signal pump problems, potentially due to blockage or failure, demanding pump inspection or replacement. The F.75 code points to a flame detection error, often linked to a faulty flame sensor or gas supply issue.

Furthermore, F.1 suggests a gas supply or ignition fault, requiring a Gas Safe engineer’s assessment. Ecotec models also present diagnostic codes like d.00, influencing heating load adjustment. Regularly checking the display for these codes and understanding their implications is crucial for maintaining optimal performance and preventing extensive damage. Promptly addressing these faults ensures continued efficient heating and hot water supply.

Turbomax Faults

Turbomax boilers, while robust, can exhibit specific error codes demanding attention. Similar to the Ecotec range, F.28 and F.29 frequently indicate a frozen condensate pipe, requiring immediate inspection and thawing, especially during winter. F.61/F.62 codes signal pump issues, potentially stemming from blockages or pump failure, necessitating professional evaluation and possible replacement. A F.75 error suggests a flame detection problem, often linked to a faulty sensor or gas supply interruption.

Additionally, F.1 points towards gas supply or ignition faults, requiring a qualified Gas Safe engineer. Turbomax models also utilize diagnostic codes, such as d.00 for heating load adjustment. Consistent monitoring of the display for these codes is vital for proactive maintenance. Addressing these faults promptly prevents escalating issues and ensures continued efficient operation, providing reliable heating and hot water throughout the year.

Ecomax Faults

Vaillant Ecomax boilers present a distinct set of potential faults, signaled through their display panel. The common F.28 and F.29 errors, mirroring other models, indicate a frozen condensate pipe – a frequent winter issue demanding immediate attention. A F.1 code typically signifies a problem with the gas supply, ignition, or a need for gas valve adjustment, requiring a qualified engineer’s expertise. Pump-related issues are often flagged by F.61 and F.62, potentially due to blockages or pump failure.

Furthermore, the F.75 error points to a flame detection problem, potentially caused by a faulty sensor. Ecomax boilers also benefit from diagnostic codes like d.00, used for heating load adjustment. Regularly checking the display and understanding these symbols allows for early fault detection, preventing more significant and costly repairs, and ensuring consistent, reliable heating performance.

Troubleshooting Common Issues

Addressing display symbols like low water pressure or a fluctuating flame requires careful observation and, often, simple adjustments to restore optimal boiler function.

Low Water Pressure Symbol

The low water pressure symbol on a Vaillant boiler, often depicted as a droplet or a pressure gauge indicating a low level, signals a critical issue needing immediate attention. Typically, a healthy system operates between 1 and 1.5 bar; anything below 0.5 bar necessitates action. This doesn’t always indicate a leak, though that’s a possibility.

Common causes include bleeding radiators to release trapped air, which can falsely lower the displayed pressure. If bleeding doesn’t resolve the issue, check for visible leaks in radiators, pipes, and the boiler itself. A hidden leak within the system is also possible. If no leaks are found, the issue might stem from a faulty pressure relief valve or a problem with the filling loop.

To temporarily resolve low pressure, you can use the filling loop to top up the system. However, consistently low pressure indicates an underlying problem requiring professional diagnosis and repair. Ignoring this symbol can lead to boiler inefficiency and potential damage.

Flame Symbol – What it Indicates

The flame symbol on your Vaillant boiler display carries significant meaning, representing the boiler’s attempt to ignite and maintain a flame for heating. A solid, steady flame icon signifies normal operation – the boiler is successfully burning gas and providing heat. However, a flashing flame symbol, or one accompanied by a fault code, indicates a problem with ignition or flame detection.

Potential causes range from minor issues like a temporary gas supply interruption to more serious concerns such as a faulty ignition electrode, a failing flame detection sensor, or issues with the gas valve. A weak or intermittent flame can also trigger this symbol.

If the flame symbol flashes and the boiler fails to ignite, avoid repeated attempts to restart it. This could lead to gas buildup. Instead, consult the boiler’s manual or, ideally, a Gas Safe registered engineer to diagnose and rectify the underlying issue safely and effectively. Ignoring a flame-related fault can be dangerous.

Temperature Display Variations

Vaillant boiler temperature displays offer crucial insights into system performance, but variations can occur. The central heating temperature shows the water heated for your radiators, while the hot water temperature indicates the water heated for taps and showers. Fluctuations are normal during operation as the boiler cycles to maintain setpoints.

However, significant or unexpected temperature changes warrant investigation. A consistently low central heating temperature might suggest insufficient boiler output, potentially due to scale buildup or a faulty pump. Conversely, excessively high temperatures could indicate a thermostat malfunction or a problem with the boiler’s control system.

Pay attention to discrepancies between set and actual temperatures. If the display shows a temperature significantly different from your desired setting, consult the manual or a qualified engineer. Understanding these variations helps ensure efficient heating and hot water delivery.

Preventative Maintenance

Regular servicing is vital for Vaillant boilers, ensuring optimal performance and longevity. Checking the condensate pipe and bleeding radiators are key maintenance tasks.

Regular Servicing Importance

Annual servicing by a Gas Safe registered engineer is paramount for maintaining your Vaillant boiler’s efficiency and safety. A qualified technician will thoroughly inspect all components, identifying potential issues before they escalate into costly repairs. This proactive approach extends the boiler’s lifespan, ensuring reliable heating for years to come. Servicing includes checking gas pressure, flue integrity, and combustion efficiency, optimizing performance and minimizing energy consumption.

Furthermore, regular maintenance ensures compliance with warranty requirements, protecting your investment. Ignoring servicing can lead to carbon monoxide leaks, posing a serious health risk to your household. A well-maintained boiler operates more quietly and efficiently, contributing to a comfortable and safe home environment. Don’t underestimate the value of preventative care – it’s a small price to pay for peace of mind and a consistently warm home.

Checking the Condensate Pipe

The condensate pipe, crucial for high-efficiency boilers, can freeze during colder months, triggering F.28 or F.29 error codes. Regularly inspect the pipe – typically a plastic pipe exiting your property – for any signs of ice formation, particularly during prolonged freezing temperatures. Gently pour warm (not boiling!) water over the pipe to thaw it, ensuring you avoid direct contact with any electrical components.

Prevention is key; insulate the pipe with suitable lagging material to minimize the risk of freezing. Ensure the pipe has a sufficient fall to allow condensate to drain freely. Clear any obstructions, such as leaves or debris, around the pipe’s outlet. If the pipe repeatedly freezes, consult a Gas Safe engineer to investigate potential issues with the pipe’s installation or insulation. Ignoring a frozen condensate pipe can lead to boiler lockout and potential damage.

Bleeding the Radiators

Trapped air within your radiators reduces heating efficiency, causing cold spots and requiring your Vaillant boiler to work harder. Regularly bleeding radiators is a simple maintenance task. Use a radiator key to slowly open the bleed valve, located usually at the top side of the radiator. Allow air to escape until water starts to emerge – have a cloth ready to catch any drips!

Work your way through all radiators, starting with those furthest from the boiler. After bleeding, check your boiler pressure; it may have dropped. If so, top it up to the recommended level (usually between 1 and 1.5 bar) using the filling loop. Consistent air in the system can indicate a larger issue, like a leak or corrosion, so if bleeding becomes a frequent necessity, consult a qualified heating engineer for a thorough system check.

When to Call a Professional

Complex faults and gas-related issues demand expert attention; always engage a Gas Safe registered engineer for safety and effective boiler repairs and servicing.

Gas Safe Registered Engineers

Employing a Gas Safe registered engineer is paramount when dealing with Vaillant boiler issues, particularly those indicated by display symbols or fault codes. These professionals possess the necessary qualifications, skills, and legal authorization to work safely with gas appliances. A Gas Safe engineer will accurately diagnose the problem, ensuring a correct and lasting repair, avoiding potential hazards associated with incorrect handling of gas systems.

Verification of registration is simple – check the Gas Safe Register website (gassaferegister.co.uk) to confirm the engineer’s credentials; Attempting DIY repairs on a gas boiler is extremely dangerous and illegal. Qualified engineers understand the intricacies of Vaillant boilers, interpreting display symbols and utilizing diagnostic tools to pinpoint the root cause of the issue. They can also provide valuable advice on preventative maintenance, extending the lifespan of your boiler and ensuring efficient operation. Prioritize safety and compliance by always choosing a Gas Safe registered professional.

Complex Faults Requiring Expert Attention

Certain Vaillant boiler issues, signaled by persistent or unusual display symbols, necessitate the expertise of a qualified heating engineer. Faults involving the gas supply, ignition system, or intricate electronic components should never be attempted as DIY repairs. These systems demand specialized knowledge and diagnostic equipment for safe and effective resolution.

Ignoring complex faults can lead to escalating problems, potential safety hazards like carbon monoxide leaks, and costly damage to the boiler. Error codes like F.75 (Flame Detection Error) or those related to pump issues (F.61/F.62) often indicate deeper underlying problems. A professional can accurately interpret these codes, conduct thorough system checks, and implement appropriate repairs. Don’t hesitate to seek expert help if you’re unsure about the meaning of a display symbol or if a simple reset doesn’t resolve the issue. Prioritize safety and long-term boiler health.

Safety Precautions

When addressing any Vaillant boiler issue, prioritizing safety is paramount. Never attempt repairs involving gas or electrical components without being a Gas Safe registered engineer. Ignoring this crucial rule can lead to severe consequences, including gas leaks, explosions, or carbon monoxide poisoning – a silent and deadly threat.

Always turn off the boiler and isolate the gas supply before undertaking any inspection or maintenance. If you detect a gas smell, immediately open windows, evacuate the premises, and contact the emergency gas helpline. Do not use any electrical switches or devices that could create a spark. Familiarize yourself with the location of your carbon monoxide detector and ensure it’s functioning correctly. If unsure about any aspect of boiler safety, always consult a qualified professional. Your well-being and the safety of your household depend on it.